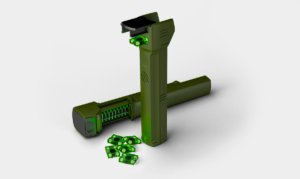

Linear Guidance Illumination (LGI)

Illuminating safe routes with LED markers

- Concept Design

- Design Engineering

- CAD

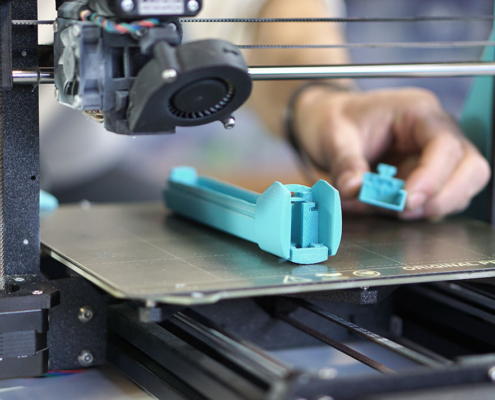

- Rapid Prototyping

- Testing

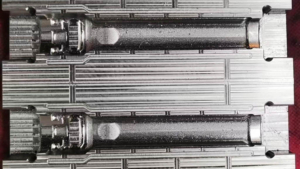

- Design for Manufacture

- Tolerancing

- Limits Testing

- Supplier sourcing

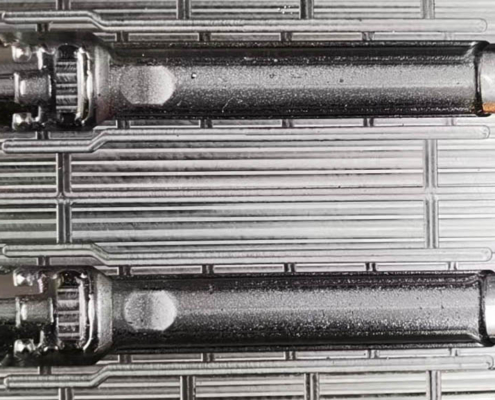

- Injection Moulding

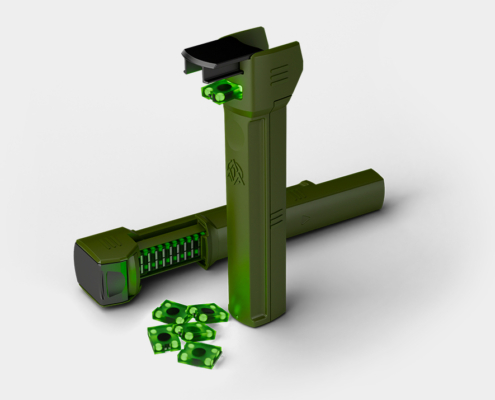

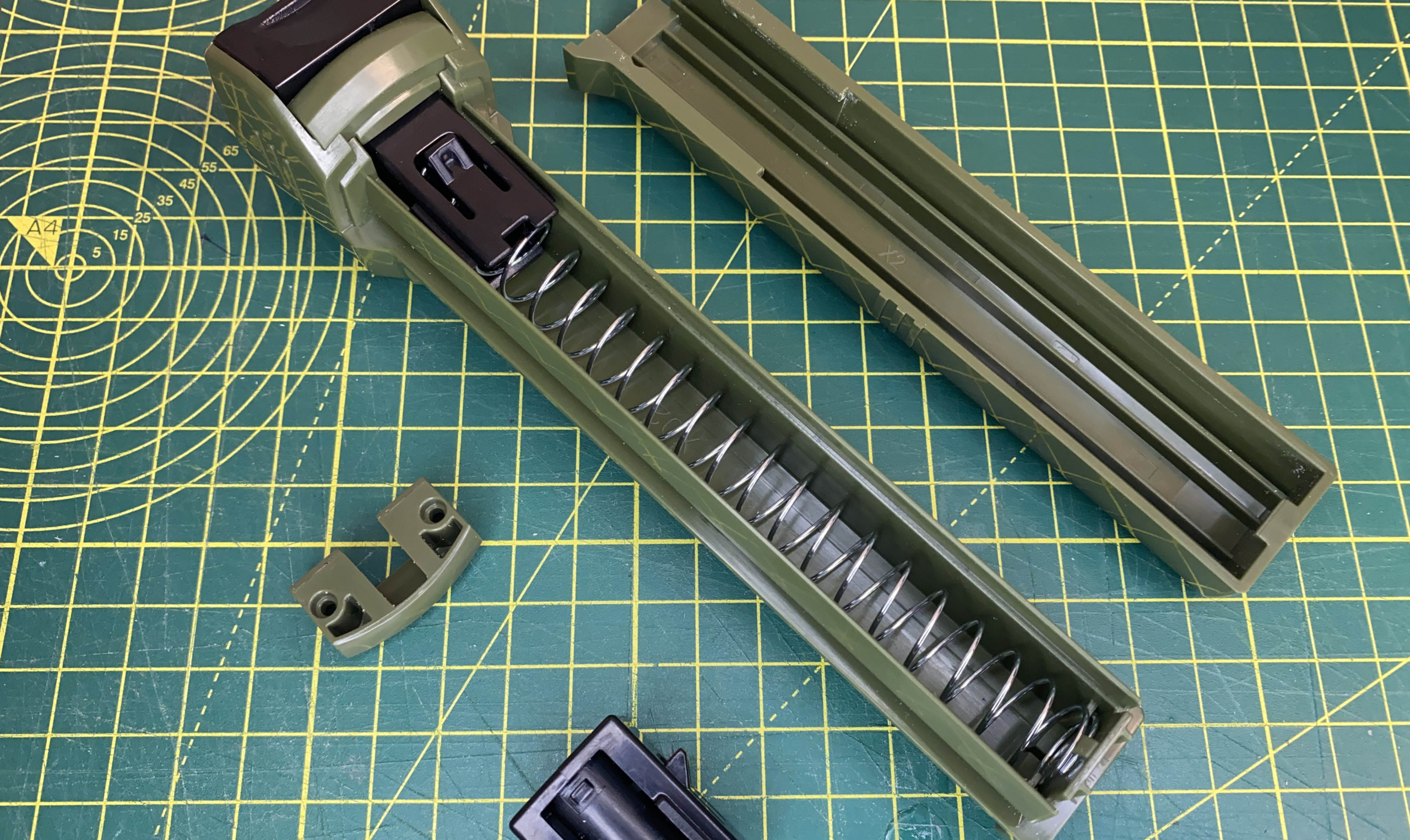

LGI tasked Neatt with designing a compact, innovative dispenser capable of securely holding LED markers while enabling automatic activation upon ejection. With a compact timeline to take the dispenser from concept to production, we were more than ready to rise to the challenge.

LGI had developed LED battery-powered markers for NATO and emergency services personnel, providing a reliable means to create safe pathways instantly, in any setting.

The dispenser needed to be compact, durable, and reliable, even in demanding conditions. It was essential that the device be ergonomic, user-friendly, and operable while wearing gloves. We focused on optimising the design by minimising component count, reducing tooling investment, and ensuring smooth operation.

After presenting LGI with a range of mechanism concepts, we developed prototypes for testing and refinement, progressing to a production-ready design.

Leveraging our extensive network, we sourced the ideal manufacturing partner for LGI and oversaw pre-production, injection mould tool commissioning, and final approvals – ensuring LGI’s product was production-ready and fit for its critical purpose.

From concept to manufacture, we’re proud to have illuminated the path forward with LGI!

Available now from LGI’s website – here