Matter

Microplastic filtration to protect our oceans

- Design Engineering

- CAD

- Mechanism Design

- Seal designs

- Electronics Integration

- Design for Manufacture

- Tolerance Stack Analysis

- Technical Drawing

- Injection moulding

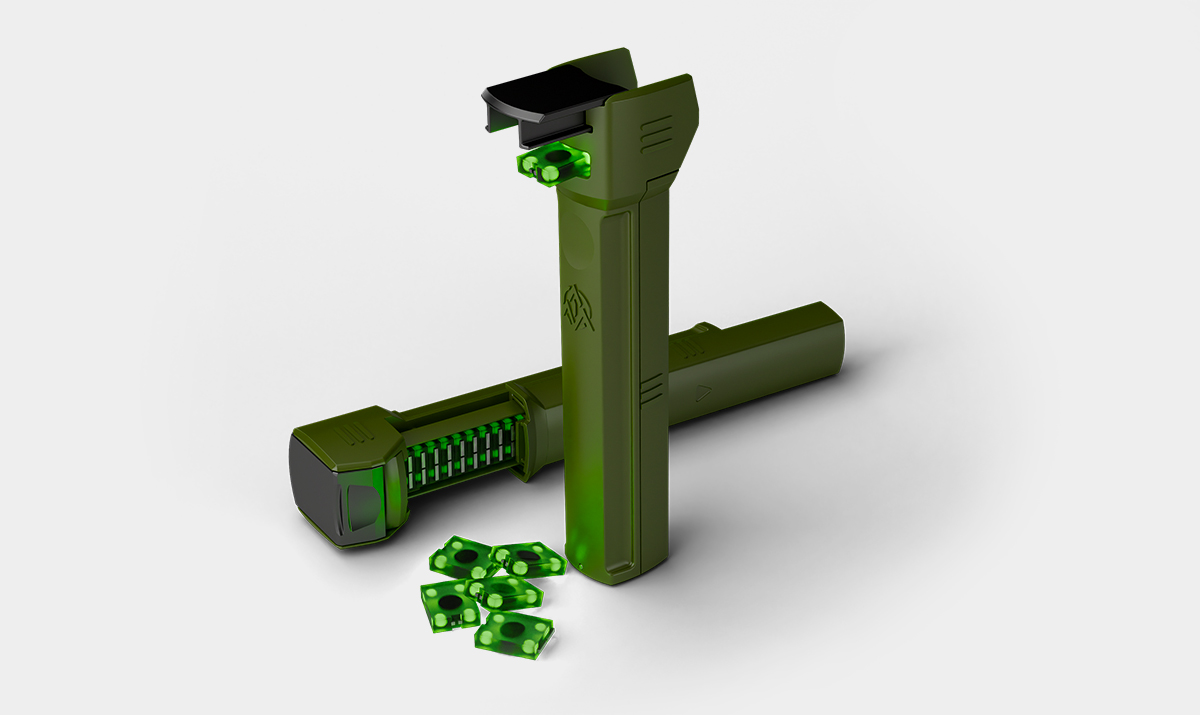

Turning the Tide on Microplastics: Neatt and Matter Collaborate on Sustainable Innovation for Cleaner Oceans.

With a shared commitment to sustainability, Neatt thoroughly enjoyed partnering with Matter on their groundbreaking microplastic filtration product, Gulp.

Designed for washing machines, Gulp’s self-cleaning filtration system captures microfibres shed from clothing, preventing them from reaching waterways and, ultimately, the ocean.

After more than a year developing Gulp’s technology into a functional prototype, Matter approached Neatt for our expertise in product design and integration of technology.

Neatt’s role then expanded to focus on preparing Gulp for high-volume manufacturing, with a robust design tailored to produce tens of thousands of units annually.

Our team tackled this challenge by ensuring the project met cost targets and was manufacturable at scale, addressing the unique complexities of Gulp’s intricate plastic components. We meticulously refined the design, creating production-ready CAD models and drawings, before conducting rigorous tolerance analysis to ensure it was toolable and durable in mass production.

Together, we’re making waves in design engineering – one microplastic filter at a time!

Read more about Matter and Gulp – here